Umatshini wokuwelda udibanisa izinto ezimbini zokuwelda (ishiti lenickel, iseli yebhetri, isibambi sebhetri, kunye nepleyiti yokukhusela njl.njl.) kunye ngokudibanisa indawo. Umgangatho we-spot welding ichaphazela ngokuthe ngqo ukusebenza ngokubanzi, isivuno, kunye nobomi bebhetri bepakethi yebhetri. Ukuwelda indawo embi nako kunokubangela umngciphekoibhetri yesiphaluka esifutshane.

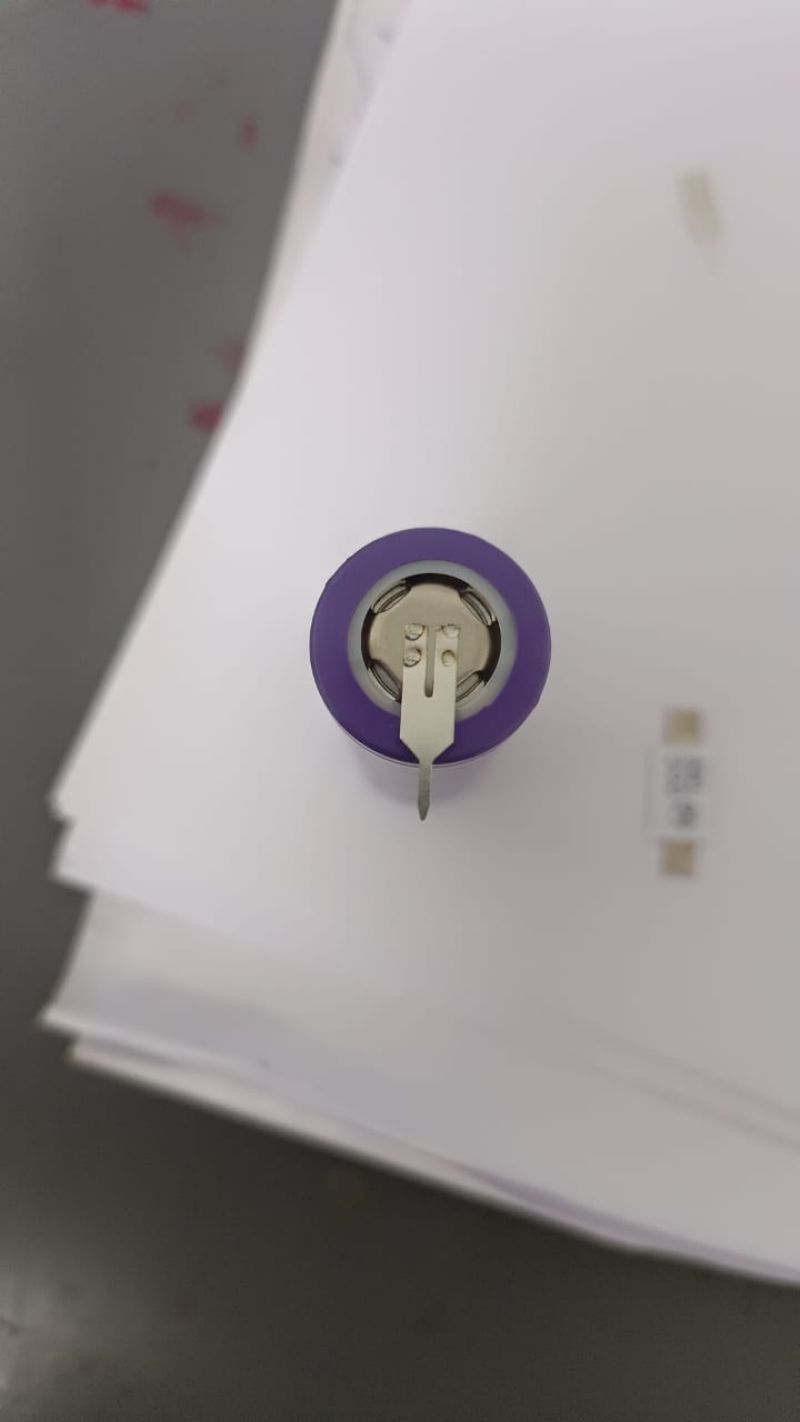

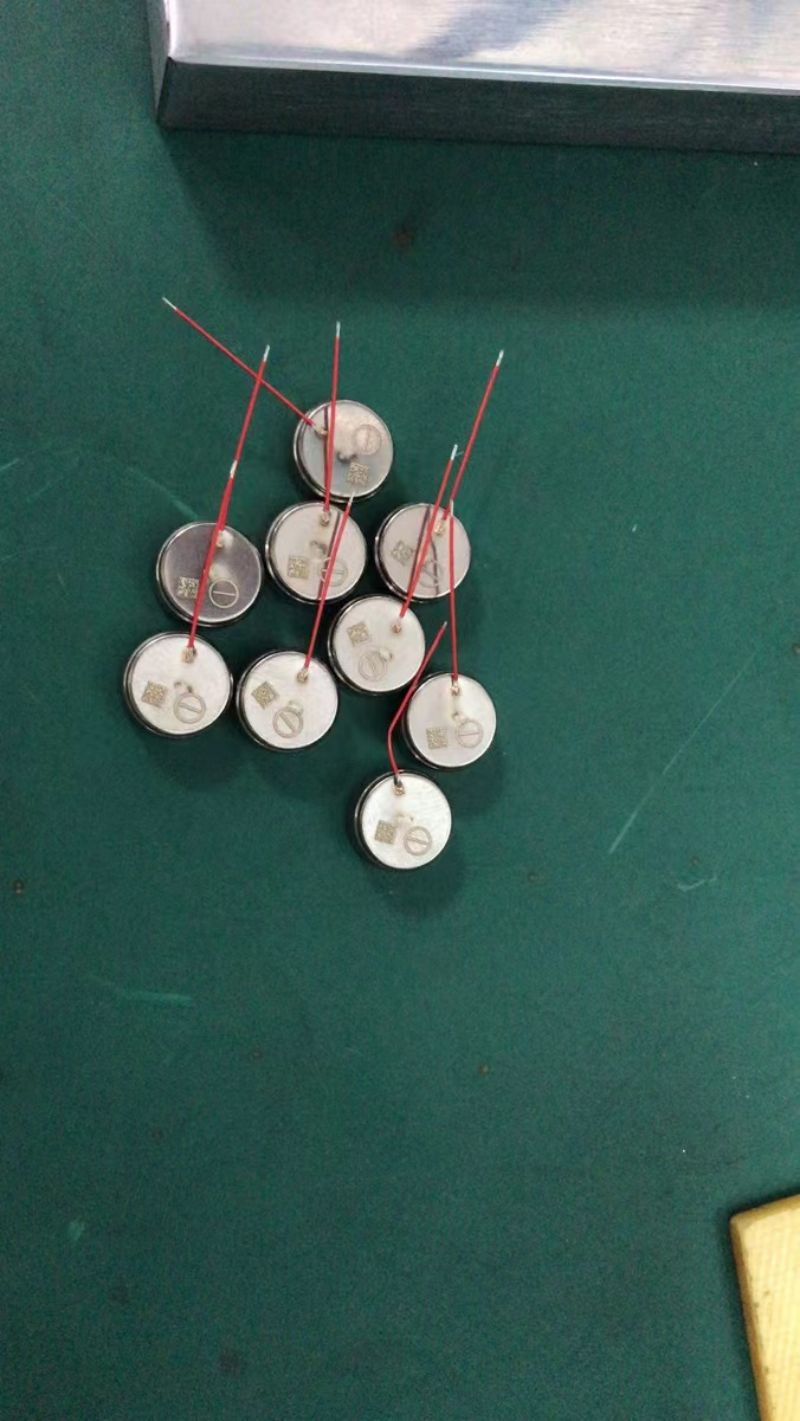

Nazi ezinye iisampulu ezineziphumo ze-welding eneziphene:

Umatshini wokuwelda indawo yebhetri yi-high-effective and high-precision high-precision welding equipment, kunye neyona nkqubo yokuwelda ibhetri ngokubanzi ibandakanya ukulungiselela ukuwelda kwangaphambili, inkqubo yokuwelda, kunye nonyango lwe-welding post. Kwinqanaba lokulungiselela phambi kwe-welding, kuyimfuneko ukubeka ibhetri kwi-weldingumzobo, inquma indawo ye-welding, kwaye ilungelelanise iiparitha. Ngexesha lenkqubo welding, indawo yebhetri welding umatshini inyibilika intsimbi phakathii-electrode yebhetringokusebenzisa ubushushu obuphezulu kunye neendlela zoxinzelelo oluphezulu, ukwenza indawo eqinileyo ye-welding. Kwinqanaba le-welding ye-post, kuyimfuneko ukususa ibhetri edibeneyo kwi-fixture, kwaye wenze ukucoca, uvavanyo kunye nezinye.unyango olusebenzayo.

Ngaphaya koko, ezinye iintsalela okanye izinto ezingcolisayo zisenokwenziwa ngexesha lenkqubo yokuwelda. Ezi ntsalela zinokuba neempembelelo ezithile kokusingqongileyo nakwimpilo yabantu. Ngokomzekelo, i-slag ye-welding kunye nee-oxide zetsimbi zinokukhutshwa kwindalo kunye ne-exhaust gas kunye namanzi amdaka, okuchaphazela umgangatho wamanzi kunye nokusingqongileyo kwe-atmospheric; I-electrode powder ingaba yingozi kwinkqubo yokuphefumula kunye nesikhumba sabaqhubi. Ngoko ke, kubalulekile ukukhetha imodeli efanelekileyoizixhobo zokuwelda indawongenxawelding echanekileyoyeiipakethi zebhetri.

Oko kwathiwa, ngokusebenzisaIsixhobo sokuwelda i-Styler's transistor precision spot, inkqubo ye-welding inokugqitywa ngexesha elifutshane, kunye nefuthe elincinci lobushushu be-welding, kwaye akukho ukutshiza ngexesha lenkqubo ye-welding. Akufanelekanga kuphela kwi-welding echanekileyo, kodwa kunye nokuncinci, ukusebenza okuphezuluizixhobo ze-elektroniki, kunye nendibano yamacandelo amancinci kwishishini lomatshini oluchanekileyo. Umzekelo, iingcingo ezincinci, iibhetri zeqhosha, oonxibelelwano abancinci be-relays, kunye ne-metal foil.

Isixhobo sokuwelda esichanekileyo sika-Styler sineendlela ezintlanu zokulawula: ngoku rhoqo, i-voltage engaguqukiyo, indibaniselwano yangoku kunye nendibaniselwano yombane engaguqukiyo, amandla angaguqukiyo, kunye neendlela zokudityaniswa kwamandla angatshintshiyo, atshintshelwa ngesandla; Iiseti ezingama-32 zokhetho lwamandla zitshintshelwa kumazibuko angaphandle; Igalelo kunye nemveliso yeempawu zesignali ziyafumaneka ezihambelana nomgca wemveliso ozenzekelayo; Umsebenzi wokubona owakhelwe-ngaphakathi: Phambi kombane osesikweni, kungakho ubhaqo lwangoku ukuqinisekisa ubukho kunye nobume bomsebenzi.

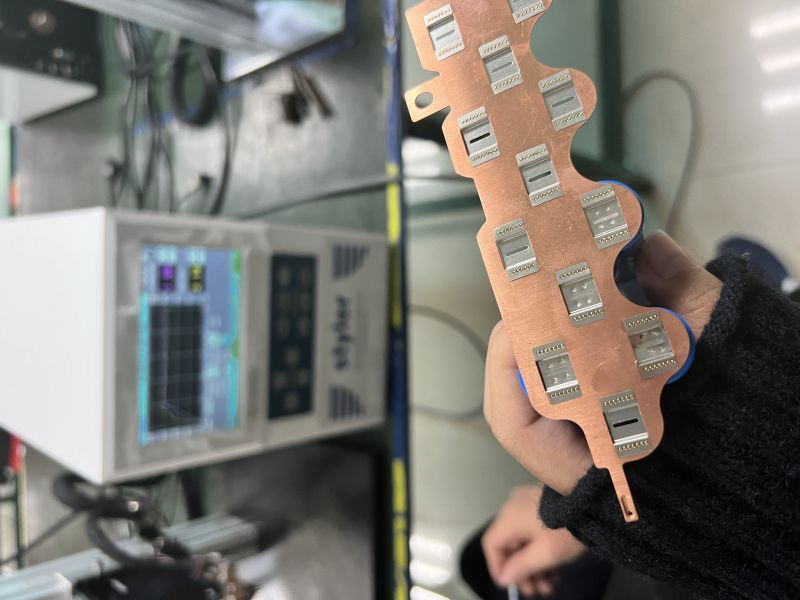

Oku kulandelayo ngumboniso wepakethi yebhetri edityanisiweyo kusetyenziswa iStyler's PDC10000A transistor precision welding equipment:

Ukuba ukhangele umatshini wokuwelda ofanelekileyo kwishishini lakho, nceda uqhagamshelane nathi namhlanje, okanye ujonge iphepha lemvelisoPDC10000A transistor echanekileyo izixhobo zokuwelda

Ulwazi olunikelwe nguStyler (“thina,” “thina” okanye “okwethu”) kwi-(“iNdawo”) yenzelwe iinjongo zolwazi ngokubanzi kuphela. Lonke ulwazi kwiSayithi lunikezelwe ngokholo oluhle, nangona kunjalo, asenzeli ukumelwa okanye iwaranti yalo naluphi na uhlobo, olucacileyo okanye oluchaziweyo, malunga nokuchaneka, ukufaneleka, ukunyaniseka, ukuthembeka, ukufumaneka okanye ukuphelela kwayo nayiphi na ingcaciso kwiSayithi. NAPHANTSI KWAYO AKUKHO IMEKO SIYA KUTHEMBELA KUWE NGAYO NAKUPHI NA Ilahleko OKANYE UMONAKALO WALO NALUPHI UHLOBO OLWENZIWE NGENXA YOKUSETYENZISWA KWESIZA OKANYE UKUXHOMEKEZWA KULO NALUPHI ULWAZI LUNIKEZELWE KWISIZA. UKUSETYENZISWA KWAKHO KWESIZA KWAYE UKUXHOMELA KWAKHO KULO NALUPHI ULWAZI KWISIZA KUSEMNGCIPHEkweni WAKHO KUPHELA.

Ixesha lokuposa: Sep-08-2023