Ngeebhetri ze-lithium ezifunwa kakhulu, abavelisi bafuna iindlela ze-welding ezilinganisa isantya, iindleko kunye nomgangatho.Ukuwelda indawokwayewelding laserlukhetho oluphezulu-kodwa leliphi elilungele umgca wakho wemveliso?

I-Spot Welding: Iyakhawuleza, ithembekile, kwaye inexabiso elisebenzayo

I-Spot welding ibe yindlela yokuya kwi-lithium ye-battery assembly, ngakumbi kwiibhasi ze-nickel kunye neeseli ze-cylindrical. Isebenza ngokuthumela i-pulse yombane ekhawulezayo ukuze idibanise isinyithi, idala amajoyina anamandla kunye nomonakalo omncinci wokushisa kwiindawo ezingqongileyo.

(Ityala: iPixabay Imifanekiso)

Kutheni ukhetha indawo yokuwelda?

I-1) Ingqinwe kwimveliso yobuninzi-Iyakhawuleza, iyaguquguquka, kwaye inexabiso elifanelekileyo, iyenza ilungele i-EV ephezulu kunye nokuveliswa kwebhetri yabathengi.

2)Ilungile kwi-nickel-Isebenza ngokugqwesileyo kakuhle nge-nickel busbar, into eqhelekileyo kwiipakethi zebhetri.

Kwi-Styler, sisebenza ngokukhethekileyo koomatshini be-welding abachanekileyo abaqinisekisa ukuphindaphinda, umgangatho ophezulu we-welds-nokuba ziiseli ezincinci ze-Li-ion okanye iimodyuli ezinkulu ze-EV zebhetri.

Ukuwelda kweLaser: Ukuchaneka okuPhakamileyo koYilo oluNxibelele

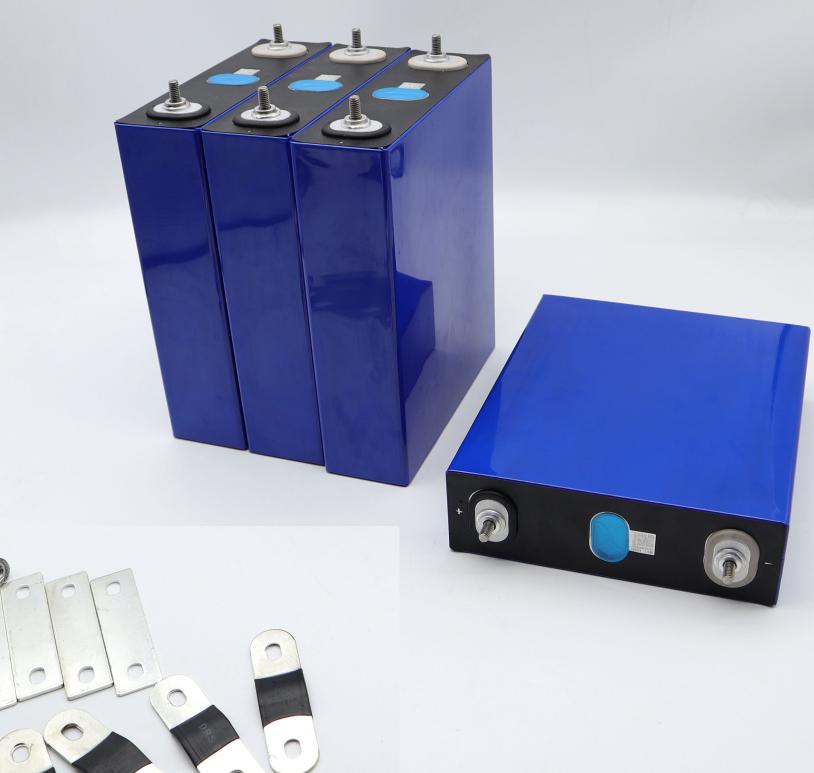

I-laser welding isebenzisa umqadi ogxininisiweyo ukunyibilika kunye nokudibanisa izinto ngokuchaneka okugqithisileyo. Lukhetho olukhethwayo lweeseli zeprismatic kunye nepouch, apho ukunyamezelana okuqinileyo kunye nokucoceka kwemithungo kubalulekile.

(Ityala: Imifanekiso yesimbo)

Ngaba ukuwelda ngelaser kunengqiqo?

I-1) i-aluminium welding-Ngokungafaniyo ne-spot welding, iilaser zibamba i-aluminium ngokufanelekileyo.

I-2)Iimeko ezisebenzayo-Ifanelekile kwiibhasi zentsimbi ezincinci, phakathi kwazo iibhasi ze-aluminium zixhaphake kakhulu.

Iiseli ezisebenzayo-Iibhetri zePrismatic kunye neebhetri zesingxobo zezona zisetyenziswa kakhulu. Ezinye iiseli zecylindrical nazo zinokudityaniswa ngelaser. Ngokukodwa kuxhomekeke kwizinto eziphathekayo zeqokobhe leseli kunye ne-electrodes efanelekileyo kunye nebi.

Nangona kunjalo, iinkqubo ze-laser ziza neendleko eziphezulu zangaphambili kwaye zifuna ubuchule obuninzi bokusebenza.

Ngoko ke yeyiphi enengqiqo kuwe?

1) Ukusebenza ngeeseli ze-cylindrical ezisekelwe kwi-nickel? Yima kwindawo yokuwelda – iyonga iindleko kwaye ivavanyiwe edabini.

2) Ukujongana neemeko ze-aluminium okanye iiseli zesingxobo? Ukubheja kwakho kweLaser, akukho mbuzo.

Apho singena khona:

Kwa-Styler, sikhethe izisombululo ze-welding ezijongene nemingeni yokwenyani yemveliso:

1) Xa isantya singenakuxoxisana

2) Xa uhlahlo lwabiwo-mali lubalulekile

3) Xa ukungaguquguquki kungenakuchaphazeleka

Oomatshini bethu bakhelwe ukugaya imveliso ephezulu, ukuhambisa umgangatho othembekileyo wokutshintsha emva kokutshintsha.

Ixesha lokuposa: Aug-06-2025