Kumdyarho wokuhlangabezana neemfuno ezikhulayo zehlabathi zeemoto zombane kunye nokugcinwa kwamandla, abavelisi beebhetri bajongene nomceli mngeni obalulekileyo: ukwandisa imveliso ngaphandle kokubeka emngciphekweni umgangatho, ukhuseleko, okanye ukuguquguquka. Intliziyo yalo mzamo wokwandisa ikwinkqubo yokuhlanganisa, ngakumbi ukudityaniswa ngokuchanekileyo nangokuthembekileyo kweeseli zesilinda kwiimodyuli kunye neepakethi. Ingxaki apha inokuthintela umgca wonke. Isisombululo asiveli nje kwiimashini ezikhawulezayo, kodwa kwiinkqubo ezikrelekrele neziguquguqukayo:Indawo yokusebenzela yokuWelda yeModular.

Eli nqaku lihlola indlela uyilo lwe-workstation lwanamhlanje, oluyimodyuli oluguqula ngayo imveliso yeeseli ze-cylindrical ezikhawulezayo, lube yinjini ebalulekileyo yokwenziwa kweebhetri okusebenzayo nokungaguqukiyo kwixesha elizayo.

Imida yeMigca eMiselweyo neLungeleleneyo

Imigca yemveli, ezinzileyo yokuziqhelanisa yokufakelwa kweeseli yakhelwe imveliso enye. Ilungile kakhulu kwiimeko ezinomthamo ophezulu, ezixutywe kancinci. Nangona kunjalo, ishishini leebhetri liyatshintshatshintsha. Iifomathi zeseli (21700, 46120, njl.njl.), uyilo lweemodyuli, kunye noqwalaselo lwe-weld (uthotho, oluhambelanayo, i-matrix) ziyaguquka ngokukhawuleza. Umgca wemveliso oqinileyo awunakuhlengahlengiswa. Ukufakelwa ngokutsha okanye ukuphinda usebenzise izixhobo kubiza kakhulu, kubangela ukungasebenzi okukhulu, kwaye kumisa imveliso. Oku kungaguquguquki kuyingozi enkulu kwimarike ekhawulezayo.

Inzuzo yeModular: Ubukrelekrele njengeMigangatho

A indawo yokusebenza yokuwelda yemodyuli iyawutshintsha lo mgaqo. Endaweni yomgca omnye omde, ozinzileyo, imveliso yahlulwe yaba ziiyunithi ezizimeleyo, ezisebenzayo—okanye iimodyuli. Imodyuli nganye, njengesikhululo sokufaka iiseli, isikhululo sokubeka ibhasi, okanye ngokubalulekileyo, isikhululo sokufaka iintsimbi ngokuchaneka, sisiqithi esizimeleyo sokwenza izinto ngokuzenzekelayo.

Amandla olu yilo akwimigaqo yalo ephambili:

1. Ukwanda kwePlag-and-Play: Ngaba ufuna i-throughput ephezulu? Hlanganisa iimodyuli ezongezelelweyo, ezifanayo ze-welding ukuze zisebenze ngaxeshanye. Imveliso inokwandiswa okanye ilungiswe kwakhona ngaphandle kokuphazamiseka okuncinci, njengokongeza ii-nodes zekhompyutha ezisebenzayo kakhulu kwi-server cluster.

2. Ukuguquguquka Okungalinganiyo: Xa kuqaliswa ifomathi entsha yeseli okanye uyilo lwemodyuli, ziimodyuli ezithile kuphela ezifuna utshintsho—njengezixhobo okanye izixhobo zokugqibela—ezifuna ukuhlaziywa. Iziseko ezingundoqo, kuquka iinkqubo zokuhamba kunye noyilo lolawulo, zihlala zinjalo. Oku kunciphisa kakhulu ixesha lokutshintsha kunye neendleko.

3. Ixesha eliphuculweyo lokusetyenziswa kunye nokugcinwa: Ukuba imodyuli enye yokuwelda ifuna ukulungiswa, inokwahlulwa kwaye ilungiswe ngelixa eminye iqhubeka nokusebenza. Olu lwakhiwo lokucubungula oluhambelanayo lususa amanqaku okusilela okukodwa, luphucula ukusebenza kakuhle kwezixhobo ngokubanzi (OEE).

Intliziyo yeModyuli: Itekhnoloji yokuWelda ngokuGqibeleleyo

Eyona nto iphambili kwimodyuli nganye yokuwelda yiteknoloji edala iibhondi zombane nezoomatshini ezihlala zihleli, ezingaxhathisi kakhulu. Kulapho ukuthembeka kungaxoxiswana khona. Iinkqubo eziphambili zidibanisa ii-laser welders ezichanekileyo kakhulu okanye ii-resistance spot welders ezintsonkothileyo ukuhlangabezana nale mfuno.

Umzekelo, ukufaka i-Styler precision spot welder kwindawo yokusebenza ye-modular kuzisa iingenelo ezikhethekileyo zokuhlanganiswa kweseli ye-cylindrical. Ukuphuma kwayo kwamandla okuzinzileyo kunye nolawulo oluphezulu lwamandla kubalulekile ekudibaniseni izinto ezincinci, ezihlala zingafaniyo zee-cell tabs kunye neebhasi zentsimbi ze-nickel-plated. Ukwakheka kwe-weld nugget rhoqo ngaphandle kokuchitha okanye ukonakala kobushushu kwiseli ebuthathaka kubaluleke kakhulu kukhuseleko kunye nobomi obude. Xa i-welder enjalo ifakwe kwinkqubo yokuhamba ye-modular, eqhutywa yi-servo, iba yiyunithi ekwaziyo ukwenza iipateni ze-weld ezintsonkothileyo kwi-matrix yeseli ngesantya kunye nokuphindaphinda.

Ukusuka kwi-Workstation ukuya kwi-Semi-Automated Line: I-Optimal Hybrid

Ingcamango yemodyuli isasazeka ngokugqwesileyo ekudaleni imigca yokuhlanganisa ezenzekelayo. Apha, imisebenzi eyenziwa ngesandla yemisebenzi efana nokuhlolwa okubonakalayo, ukuhlanganiswa kwesixhumi, okanye ukuhanjiswa kwehashe kudityaniswe ngendlela elungelelanisiweyo kunye neemodyuli ezizenzekelayo.

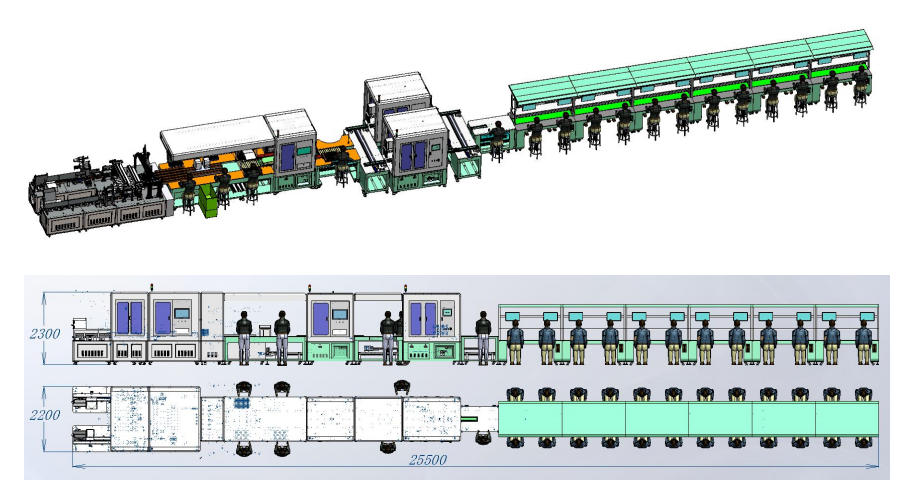

Cinga ngomgca wokuwelda we-busbar ozenzekelayo owakhelwe kwimigaqo yemodyuli. Umsebenzisi angalayisha isixhobo seseli esifakwe ngaphambili kwi-pallet. Emva koko i-pallet ingena kwisikhululo esisebenzisa i-automated esine-Styler welder, esenza zonke ii-busbar-to-tab welds ngokulungelelana okugqibeleleyo. I-pallet iqhubekela kwisikhululo esenziwe ngesandla ukuze kusetyenziswe izinto ezisetyenziswa kwi-thermal interface okanye kuhlolwe i-voltage tap, ngaphambi kokuba idlulele kwi-automated module elandelayo. Le ndlela ye-hybrid ilinganisela ukuguquguquka kunye nokugweba kwabasebenzi abangabantu ngesantya, ukuchaneka, kunye nokuhambelana kwe-automation apho kubaluleke kakhulu - kwindawo yokuwelda.

Isiphelo: Ukwakha Ikamva, Namhlanje

Kubavelisi beebhetri, ukutyala imali kuyilo lwendawo yokusebenza yokuwelda yemodyuli kutyalo-mali ekuqineni nasekukhuleni. Kuguqula umgangatho wemveliso ukusuka kwityathanga elingashukumiyo nelibuthathaka ukuya kwinethiwekhi enamandla nehlengahlengiswayo. Ngokudibanisa ubuchwepheshe obuchanekileyo obufana nabawelda abaphambili kolu lwakhiwo oluguquguqukayo, iinkampani zinokufikelela kwinqanaba elingcwele lokuvelisa izinto zanamhlanje: imveliso ekhawulezayo, umgangatho ongagungqiyo, kunye nobuchule bokuziqhelanisa neemfuno zangomso.

Le injini yemodyuli ayisebenzisi nje kuphela amandla emigceni yemveliso yanamhlanje; ikwakhuthaza ukuveliswa kweebhetri zexesha elizayo.

Ulwazi olubonelelwe nguIsitayilekuvuliwehttps://www.stylerwelding.com/ Yenzelwe iinjongo zolwazi ngokubanzi kuphela. Lonke ulwazi olukwiSayithi lunikezelwa ngokunyaniseka, nangona kunjalo, asiwenzi siqinisekiso salo naluphi na uhlobo, olucacileyo okanye olungachazwanga, malunga nokuchaneka, ukwanela, ukuthembeka, ukuthembeka, ukufumaneka okanye ukuphelela kwalo naluphi na ulwazi olukwiSayithi. NGAPHANTSI KWAYO NGABA SISIYIKUBA NOXANDUVA KUWE NGENXA YOKULAHLEKA OKANYE UMONO WALO NALUPHI NA UHLOBO OLUVEYO NGENXA YOKUSETYENZISWA KWESAYITI OKANYE UKUTHEMBEKA KULO NALUPHI NA ULWAZI OLUNIKELWE KWISAYITI. UKUSETYENZISWA KWAKHO KWESAYITI NOTHEMBEKA KWAKHO KULO NALUPHI NA ULWAZI OLULISELE KWISAYITI KUSEMNGCIPHEKWENI WAKHO WONKE.

Ixesha leposi: Disemba-31-2025