Kwimveliso yebhetri ye-lithium-ion, ukusebenza kwe-welding kuchaphazela ngokuthe ngqo ukuqhuba, ukhuseleko, kunye nokungaguquguquki kwebhetri elandelayo.Ukumelana nendawo yokuweldakwayewelding laser, njengeenkqubo eziqhelekileyo, nganye ineempawu ezihlukeneyo, ezenza ukuba zilungele izinto ezahlukeneyo zebhetri kunye nezigaba zesakhiwo.

I-Resistance spot welding: Indlela ekhethiweyo yokuwelda amaphepha e-nickel

I-Resistance spot welding isebenzisa ubushushu obunganyangekiyo obuveliswa ngokudlula kwi-nickel sheets ukwenza ibhondi eyomeleleyo ye-metallurgical. Ubushushu obugxininisiweyo kunye nenkqubo ye-welding ekhawulezayo yenza ukuba kube yinto efanelekileyo kwizixhobo ze-welding ezifana ne-nickel ecocekileyo okanye i-nickel ribhoni, esetyenziswa ngokuqhelekileyo kwiibhetri ze-lithium-ion. Izibonelelo zayo zixhomekeke kwiindleko-zokusebenza kunye nenkqubo evuthiweyo, iyenza ibe lukhetho oluthembekileyo lwe-welding yomthamo ophezulu weethebhu zeeseli zebhetri kunye nezihlanganisi.

(Ityala: Imifanekiso yesimbo)

(Ityala: Imifanekiso yesimbo)

Laser welding: Indlela echanekileyo yokuwelda ialuminiyam kunye nemathiriyeli engqindilili

Xa welding i-aluminium casings, izihlanganisi ze-aluminiyam, okanye izinto ezityebileyo zesakhiwo, i-laser welding ibonisa iingenelo zayo ezizodwa. Uxinaniso lwamandla oluphezulu kakhulu lwelaser luyivumela ukuba ilawule i-aluminium busbar eshinyeneyo, iphumeze i-welds yokungena enzulu kwaye ivelise iiweldi ezithandekayo, ezingenamoya. Ilungele ukuchaneka kokujoyina amacandelo e-aluminium kwiimodyuli zebhetri kunye neepakethi.

(Ityala: Imifanekiso yesimbo)

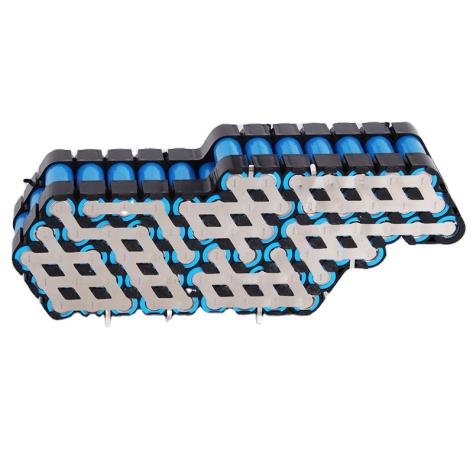

Inkqubo epheleleyo yoyilo lomgca wemveliso ukusuka kwiseli ukuya kwipakethe

Umgca opheleleyo wokuvelisa ibhetri ye-lithium ngokuqhelekileyo udibanisa iinkqubo ezininzi. Ngokusekelwe kwizinto zakho ezithile (i-nickel / i-aluminium / ithusi) kunye nesakhiwo sokupakisha ibhetri, sinokudibanisa amanyathelo afana nokuhlelwa kweeseli kunye ne-busbar welding, ukusuka kwiiseli zomntu ngamnye ukugqiba iipakethi zebhetri, ukudala izisombululo zokuvelisa ezilungiselelwe kunye neziguquguqukayo ezilinganisa ukusebenza kakuhle, iindleko kunye nokusebenza.

Kwimveliso yebhetri, akukho sisombululo sokuwelda silingana nesinye. Iindidi ezahlukeneyo zebhetri zihlala zifuna iinkqubo ezithile ze-welding. Siyayiqonda le nto kwaye sizibophelele ekuboneleleni ngoluhlu olubanzi lwezixhobo zokuwelda ukukunceda ufumane eyona ndlela ilungileyo. Kwa-Styler, sibonelela ngaphezu kwezixhobo nje; sinikezela ngendlela yenkqubo elungiselelwe iimfuno zakho. Thetha nathi kwaye masisebenzise eyona teknoloji ifanelekileyo yokuwelda ukukhusela ibhetri yakho.

Want to upgrade your technology? Let’s talk. Visiting our website http://www.styler.com.cn , just email us sales2@styler.com.cn and contact via +86 15975229945.

Ixesha lokuposa: Oct-15-2025