Kwihlabathi elikhula ngokukhawuleza lokwenziwa kweebhetri-ukunika amandla yonke into ukusuka kwii-EV ukuya kubathengi be-elektroniki kunye nokugcinwa kwegridi-ukuwelda kumi njengendlela ebalulekileyo, kodwa ihlala ingumngeni, inkqubo yokuhlanganisa ipakethi yebhetri. Ingqibelelo yalo lonke uqhagamshelwano luchaphazela ngokuthe ngqo ukhuseleko lwepakethi, ukusebenza kunye nobomi obude. E-STYLER, sisebenza ngokukhethekileyo kwi-welding ephezulu kunye nezisombululo zendibano zokudityaniswa kwenqanaba lokupakisha, kubandakanya ukuchaneka okuchanekileyo.Spot Welders, i-high-speed Laser Welding Machines, kunye ne-turnkey yeModyuli yebhetri kunye neMizila yeNdibano yokuPakisha.

We'Siqulunqe eyona mibuzo ilishumi ixhaphakileyo elidibana neqela lethu lobunjineli malunga nokuwelda ipakethe yebhetri, ibonelela ngeengcaphephe zokuqonda ukukunceda ujongane nobunzima bayo.

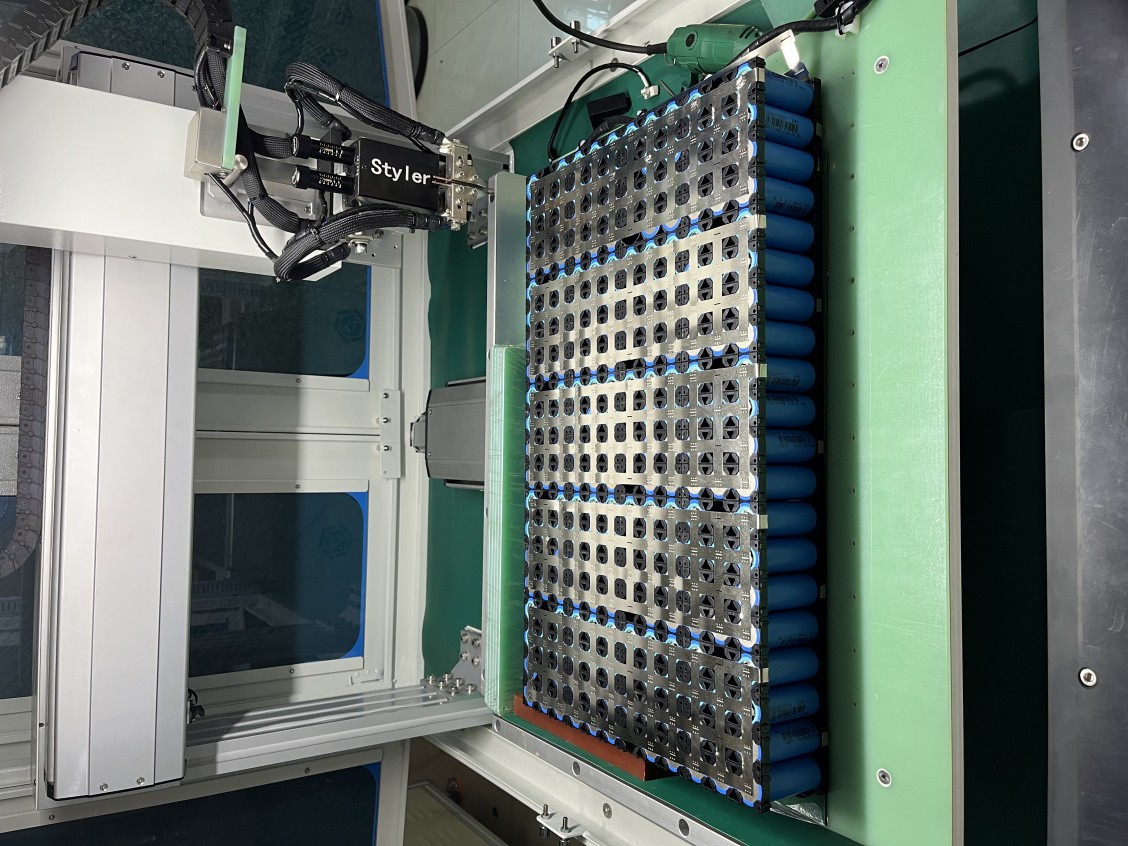

1. Yiyiphi eyona nkqubo ifanelekileyo yokudibanisa iimodyuli zeeseli ze-cylindrical okanye i-battery pack busbars?

Ukudibanisa iiseli kwiimodyuli okanye ukujoyina iibhasi ngaphakathi kwepakethi, i-Resistance Spot Welding ihlala ilukhetho olukhethiweyo. Yona'indlela ekhawulezayo, engabiziyo, kwaye ethembekileyo yokudala uqhagamshelo olomeleleyo lombane. STYLER's amabala abawelder, usebenzisa iteknoloji ye-transistor ephezulu, ukuhambisa isantya esikhethekileyo kunye nokuzinza, kunye nengxelo eqhubekayo yangoku kunye nokulawula okuguquguqukayo ukuphatha izinto ezincinci, ezibuthathaka njenge-nickel-plated busbar.

2. Sithintela njani ukushisa kunye nomonakalo wokushisa kwiiseli zebhetri ngexesha le-pack welding?

Ulawulo lwe-thermal ngexesha lokuhlanganisa ipakethi lubaluleke kakhulu. Into ephambili kukulawula igalelo lamandla ngokuchaneka ngokugqithiseleyo kwiindawo zokudibanisa. I-Transistor-based Resistance Spot Welders yethu ifezekisa oku ngokusebenzisa i-ultra-short, imijikelo ye-welding enexesha elichanekileyo (ii-milliseconds), ukunciphisa ukusasazeka kobushushu. Kwi-laser welding, ukukhetha iiparamitha ezichanekileyo kunye nokusebenzisa iiskena ze-galvanometer zesantya esiphezulu zibeka igalelo lobushushu. Iinkqubo zethu zinokudibanisa ukujongwa kwe-thermal ukuqinisekisa ukuba iiseli ezikufutshane zihlala ngaphakathi kwemida ekhuselekileyo.

3. I-aluminium kunye ne-copper-aluminiyam i-composites ixhaphake kwii-pack busbars. Ziziphi izisombululo ze-welding?

I-Welding ezi zixhobo zifuna ukukhethwa kwenkqubo ngokucophelela. Kwi-welding yendawo, i-nickel ecocekileyo i-conductivity ephezulu ifuna umbane ophezulu ngexesha elifutshane kakhulu. I-STYLER's transistor welders ihambisa i-pulse yamandla ekhawulezayo eyimfuneko, ezinzileyo. Kwi-laser welding yeebhasi ze-aluminium kunye noqhagamshelo, iyasebenza kakhulu. Nangona kunjalo, kwiibhasi zebhasi zobhedu kwindibano yepakethi, ukuwelda kwelaser kuzisa imiceli mngeni ngenxa yokubonakala okuphezulu kunye nokuhanjiswa kwe-thermal. Enye indlela esebenzayo kunye nenconywayo kukusebenzisa i-copper-aluminium composite busbars (izinto ezigqokeyo), apho i-laser weld yenziwa kwi-aluminium layer, iqinisekisa ukudibanisa okuthembekileyo kunye nokuzinza.

4. Kubaluleke kangakanani ukucoceka kwempahla kunye nokulungiswa komphezulu we-pack welding?

Igxeka kakhulu. Ii-oksidi, i-oyile, kunye nongcoliseko kwiibhasi zebhasi okanye iitheminali zibangela umgangatho we-weld ongahambelaniyo, ukwanda kokumelana nombane, kunye nokusilela okunokwenzeka. Inkqubo yokudibanisa ipakethe eyomeleleyo kufuneka iquke ukucocwa okufanelekileyo (umzekelo, ukucocwa kwelaser, ukucocwa kweplasma) kwangoko phambi kokuba kutshiswe. I-STYLER yeBattery Pack Assembly Lines inokudibanisa izikhululo zokucoca ezizenzekelayo ukuze kuqinisekiswe iimeko ezihambelanayo zomphezulu kuzo zonke uxhumano.

5. Siqinisekisa njani umgangatho we-weld ohambelanayo kwimveliso yepakethi ephezulu?

Ukungaguquguquki kuvela kuzinzo lwezixhobo, ukujonga inkqubo, kunye nokuzenzekelayo. Oomatshini bethu baquka:

Ixesha langempela lokuJonga inkqubo: Ukulinganisa ukuxhathisa okuguquguqukayo (i-spot welding) kuyo yonke i-weld.

Ulawulo lwe-Adaptive lwe-Loop evaliweyo: Ukulungelelanisa ngokuzenzekelayo iiparamitha ngokusekelwe kwimpendulo.

I-100% yokuhlolwa kwe-Post-Weld: Ukudibanisa iinkqubo zombono wokubekwa kwe-weld kunye nokuvavanya ukuchasana kombane kumgca wokuhlanganisa ukuqinisekiswa komgangatho.

6. Zeziphi iingenelo eziphambili zokuwelda kwelaser kwindibano yebettery pack?

I-Laser Welding inikezela ngokuguquguquka okukhethekileyo kwijometri ye-weld (imigca, izangqa, iicontours), uxinzelelo oluncinci lomatshini, kunye nokukwazi ukuwelda kwiindawo ezivaliweyo ngaphakathi kwesakhiwo sepakethi. Ilungele ukuwelda iipleyiti zokuphela kwemodyuli, i-cover seams (apho kufanelekileyo), kunye neemilo zebhasi ezintsonkothileyo. Inciphisa ukunxitywa kwezixhobo kwaye yenza isantya esiphezulu, i-aesthetically clean seams.

7. Ifuneka nini i-turnkey Battery Pack Assembly Line iyimfuneko vs.

I-Standalone welders ifanelekile kwi-R & D, imigca yokulinga, okanye amanyathelo athile angaphantsi kwe-assembly. I-turnkey yeBattery Pack Assembly Line iyimfuneko ekuhlanganiseni, ukuveliswa kwevolumu ephezulu yeemodyuli ezipheleleyo okanye iipakethi. I-STYLER iqulunqa imigca eyenza ngokuzenzekelayo ulandelelwano olupheleleyo: ukupakishwa kwemodyuli, ukubekwa kwebhasi, i-welding (indawo okanye i-laser), uvavanyo lombane, kunye nokuhlanganiswa kokugqibela. Oku kwandisa i-output, kunciphisa impazamo yomntu, kuqinisekisa ukulandeleka, kunye nokwandisa indawo yomgangatho.

8. Ujongana njani ne-weld spatter kwipakethi yebhetri, enokubangela iisekethe ezimfutshane?

Ukutshiza ngaphakathi kwepakethi kuyingozi enkulu yokhuseleko. Kwi-spot welding, ilawulwa ngokuphucula imo ye-weld pulse kunye namandla e-electrode. Ii-Spot Welders zethu ezisekwe kwiTransistor zibonelela ngolawulo oluphezulu lwe-pulse, zinciphisa kakhulu ukuveliswa kwe-spatter. Kwi-laser welding, ukutshiza kuncitshiswa ngokusebenzisa igesi yokukhusela echanekileyo, indawo efanelekileyo yokugxila, kunye neeparamitha ezilungiselelweyo. Iinkqubo zeSTYLER zenzelwe ukuvelisa ii-welds ezicocekileyo nezincitshisiweyo ezibalulekileyo kukhuseleko lwepakethi.

9. Zeziphi iimetriki ekufuneka sizisebenzise ukuqinisekisa umgangatho we-weld kwipakethi?

Ngaphandle kokuhlolwa okubonakalayo, iimethrikhi eziphambili zokuqinisekisa ziquka:

Ukunyangwa koMbane/Ukuqhuba: Ilinganiswe kwijoyini yeweld nganye; ukuchasana okuphantsi kunye nokuhambelanayo kubalulekile ekusebenzeni kwepakethi.

Ukutsalwa / Amandla e-Peel: Uvavanyo lokutshabalalisa oomatshini kwiisampulu zokuqinisekisa ukunyaniseka koqhagamshelo kuhambelana neenkcukacha.

Ubungakanani beNugget/Ukungena komthungo: Kuqinisekiswe ngokuhlalutywa kwamacandelo ngexesha lenkqubo yesiqinisekiso.

Inkqubo yokuLonwa kweDatha: Zonke iiparameters ze-weld (ngoku, ixesha, amandla) zirekhodwa nge-STYLER izixhobo zokulandelela imveliso epheleleyo.

10. Ishishini lilungisa njani i-welding kuyilo lwepakethi entsha njenge-CTC (i-Cell-to-Chassis) okanye iipakethi ezinkulu zesakhiwo?

Olu yilo lufuna iinkqubo ze-welding ezenza uqhagamshelwano oluqinileyo, oluthembekileyo lombane kunye nolwakhiwo ngamanye amaxesha kwizinga elikhulu. Batyhala iimfuno zobunzulu be-weld, isantya, kunye nokungaguquguquki. I-High-Power Laser Welders isetyenziswa ngakumbi kwi-welds ye-seam emide kwiindawo ezivaliweyo kunye neebhasi zesakhiwo. I-STYLER iphambili, iphuhlisa izisombululo ngamandla ayimfuneko, ukuchaneka, kunye nobuchule bokuhlangabezana nale mingeni yendibano yesizukulwana esilandelayo.

Isiphelo

Ukuwelda kwipakethi yebhetri luqeqesho oluchanekileyo olugxile ekudaleni uqhagamshelo lombane olugqibeleleyo ngaphakathi kwendibano ekhuselekileyo nethembekileyo. Ubambiswano olufanelekileyo kunye nokhetho lwetekhnoloji lugqibe kwimpumelelo yemveliso yakho.

Kwi-STYLER, sibonelela ngezisombululo ezijoliswe kuzo zokudityaniswa kwebhetri. Ukusuka kuzinzo olunesantya esiphezulu se-Transistor-based Resistance Spot Welders kunye nokuchaneka okuguquguqukayo kwe-Laser Welding Systems ukuya kwi-automation edityanisiweyo ngokupheleleyo yeMigca yeNdibano yeBattery Pack yethu, sizimisele ukuxhobisa imveliso yakho ngokuthembeka, ukusungula izinto ezintsha, kunye nokugqwesa.

Ngaba ukulungele ukuphucula inkqubo yakho yokuwelda iibhetri? Nxibelelana neqela leengcali zeSTYLER namhlanje ukuze ufumane ingcebiso.

Ixesha lokuposa: Dec-11-2025