Kumhlaba osoloko uvela wetekhnoloji yebhetri, ukufumana umatshini wokuwelda ofanelekileyo kubalulekile kwiinkqubo zemveliso ezisebenzayo nezisebenzayo. I-Styler, inkokeli kwi-teknoloji ye-welding, inikeza uluhlu lweizisombululo ezilungiselelwekwiintlobo ezahlukeneyo zebhetri kunye neemfuno zemveliso. Kwesi sikhokelo somthengi sibanzi, siza kujonga kwiingqwalasela eziphambili ukukunceda ukhetheumatshini welding ogqibeleleyokwiimfuno zakho.

1. Qinisekisa uhlobo lwebhetri

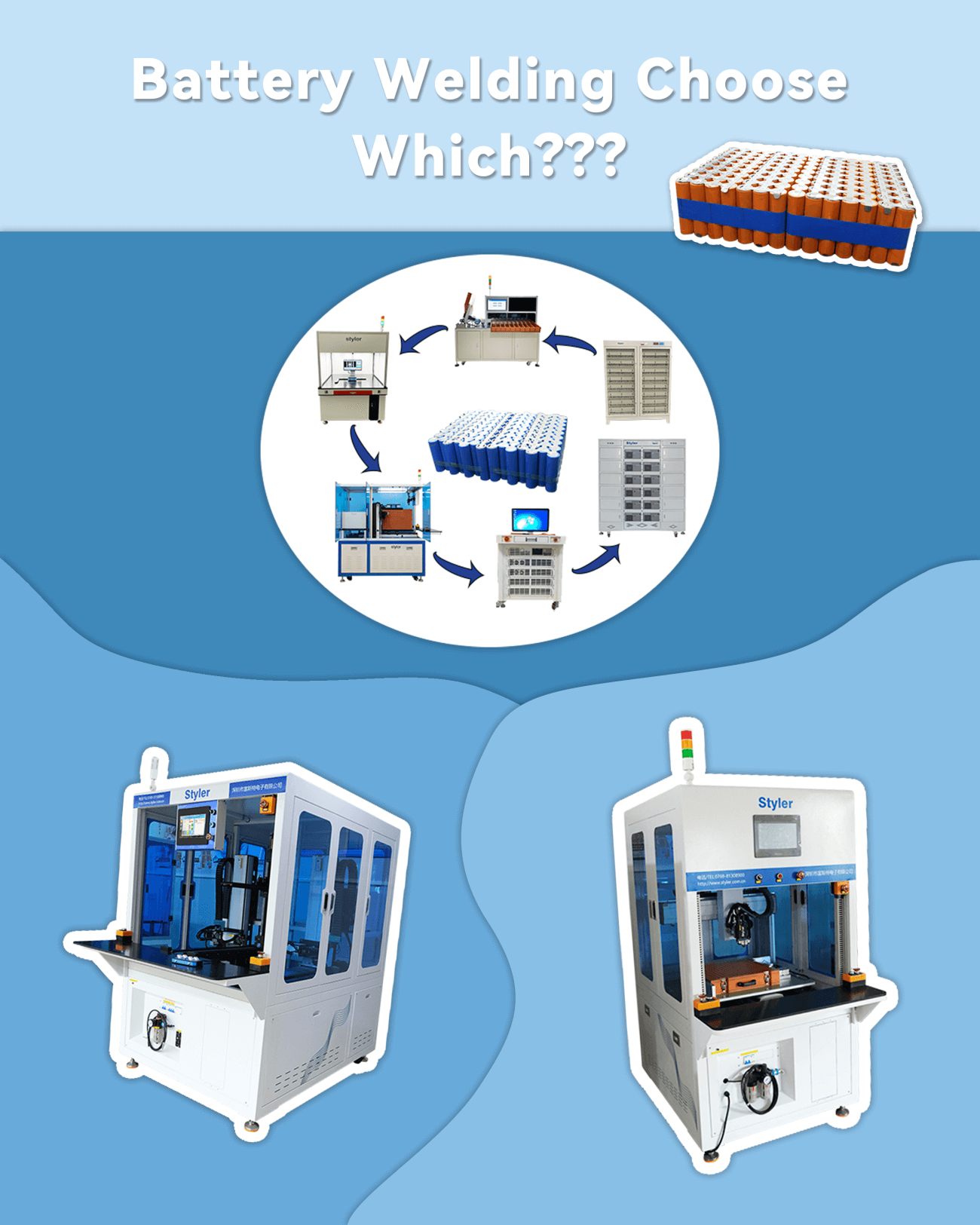

Ngaphambi kokuntywila kwihlabathi loomatshini bokuwelda, kubalulekile ukuchonga uhlobo lweebhetri oza kusebenza nazo. Ingaba i-cylindrical, i-prismatic, okanye ezinye iifomati ezikhethekileyo, i-Styler inezisombululo ezenzelwe ukuhlangabezana neemfuno ezizodwa zomntu ngamnye.

2. Qinisekisa i-Welding Materials

Iindidi ezahlukeneyo zebhetri zifuna izixhobo ezithile ze-welding ukuze zisebenze ngokufanelekileyo. Kwiiseli ze-cylindrical, i-nickel-plated okanye i-nickel ecocekileyo imicu ukusuka kwi-0.1mm ukuya kwi-0.5mm isetyenziswa ngokuqhelekileyo. Kwelinye icala, iiseli zeprismatic zihlala zisebenzisa iithebhu zealuminiyam ukusuka kwi-1mm ukuya kwi-3mm ubukhulu. Oomatshini be-styler baxhotyiswe ukuphatha ezi zixhobo ngokuchanekileyo kunye nokuthembeka.

3. Vavanya iMveliso yeMveliso

Umthamo wokuvelisa udlala indima ebalulekileyo ekukhetheni umatshini wokuwelda ofanelekileyo. Ukuveliswa kweeseli ze-cylindrical ezisezantsi, i-Styler's PDC / IPV / IPR i-welding manual series inikezela ukuguquguquka kunye nokulawula. Ukuveliswa kwevolumu ephezulu, qwalasela i-Styler's XY ngokuzenzekelayo i-single-side okanye i-double-sided welding machines. Iinketho zokwenza ngokwezifiso ezinjengeentloko ezijikelezayo kunye nokulungiswa okulungiselelwe ubungakanani bebhetri yakho ngakumbi kuphucula ukusebenza kakuhle kunye nokusebenza. Kwi-prismatic cell welding, oomatshini bokuwelda be-Styler's gantry galvanometer laser banika iinketho zamandla ukusuka kwi-1000 ukuya kwi-6000 watts, ziqinisekisa ukuhambelana nezixhobo ezahlukeneyo zethebhu kunye nobukhulu.

4. Phonononga iPack Assembly Solutions

Ukongeza koomatshini be-welding, i-Styler inikezela nge-semi-automatic kunye neenkonzo zokwenza umgca we-automatic. Iqela lethu le-R&D elizinikeleyo lisebenza ngokusondeleyo nawe ukuyila izisombululo zomgca wendibano ezihambelana neemfuno zakho, uhlahlo lwabiwo-mali, kunye nemiqobo yendawo. Ukusuka kwingcamango ukuya ekuphunyezweni, i-Styler ibonelela ngenkxaso ebanzi yokulungelelanisa inkqubo yakho yokuvelisa ipakethi yebhetri.

Ukukhetha umatshini wokuwelda ochanekileyo kubalulekile ekufezekiseni imveliso yebhetri engenamthungo nesebenzayo. Ngoluhlu olwahlukeneyo lwezisombululo ze-Styler ezilungiselelwe iintlobo ezahlukeneyo zebhetri kunye nomthamo wemveliso, unokuphakamisa amandla akho okuvelisa ngokuzithemba. Nokuba ungumsebenzi omncinci okanye isigebenga seshishini, i-Styler inobuchwephesha kunye netekhnoloji yokuhlangabezana neemfuno zakho ze-welding. Xhumana neqela lethu namhlanje ukuba liqalise uhambo olusingise kwimveliso ephuculweyo kunye nomgangatho wokwenziwa kweebhetri.

Ulwazi olunikezelwe nguIsimbokwihttps://www.stylerwelding.com/yenzelwe iinjongo zolwazi ngokubanzi kuphela. Lonke ulwazi kwiSayithi lunikezelwe ngokholo oluhle, nangona kunjalo, asenzeli ukumelwa okanye iwaranti yalo naluphi na uhlobo, olucacileyo okanye oluchaziweyo, malunga nokuchaneka, ukufaneleka, ukunyaniseka, ukuthembeka, ukufumaneka okanye ukuphelela kwayo nayiphi na ingcaciso kwiSayithi. NAPHANTSI KWAYO AKUKHO IMEKO SIYA KUTHEMBELA KUWE NGAYO NAKUPHI NA Ilahleko OKANYE UMONAKALO WALO NALUPHI UHLOBO OLWENZIWE NGENXA YOKUSETYENZISWA KWESIZA OKANYE UKUXHOMEKEZWA KULO NALUPHI ULWAZI LUNIKEZELWE KWISIZA. UKUSETYENZISWA KWAKHO KWESIZA KWAYE UKUXHOMELA KWAKHO KULO NALUPHI ULWAZI KWISIZA KUSEMNGCIPHEkweni WAKHO KUPHELA.

Ixesha lokuposa: May-24-2024