Iimveliso

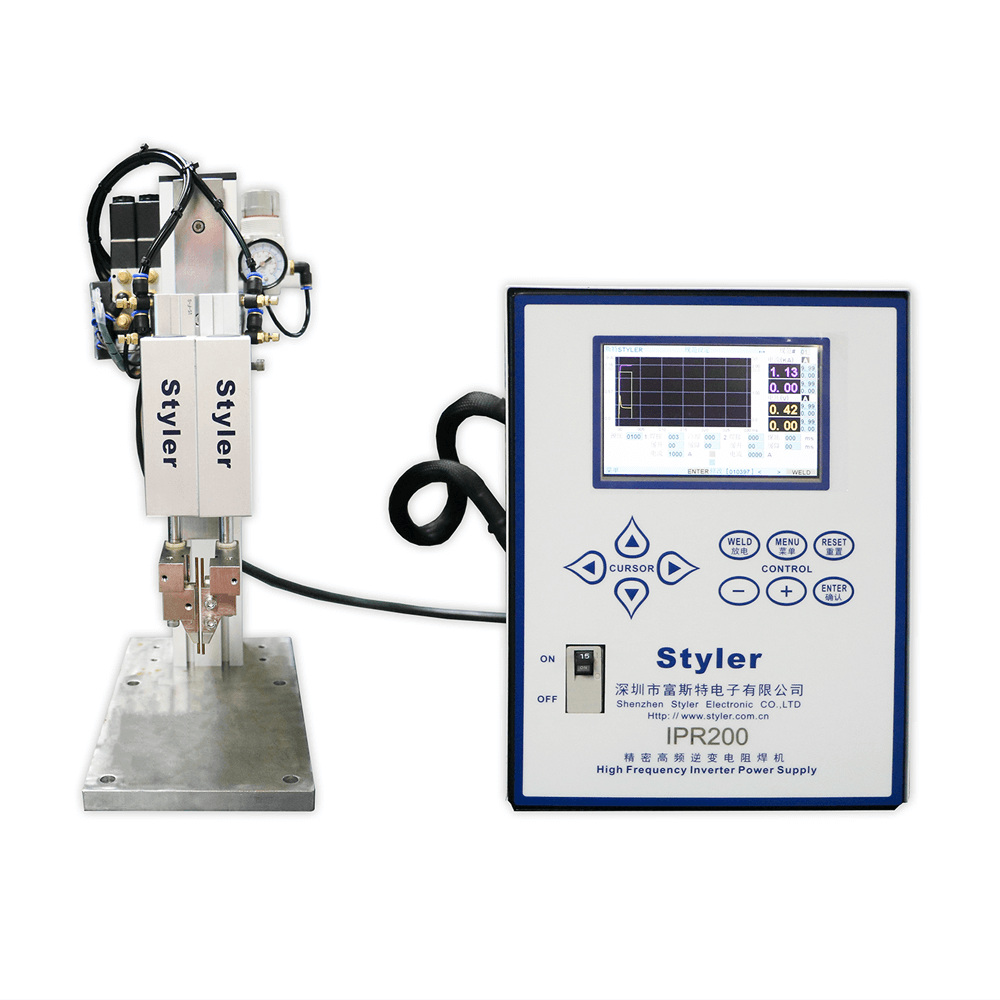

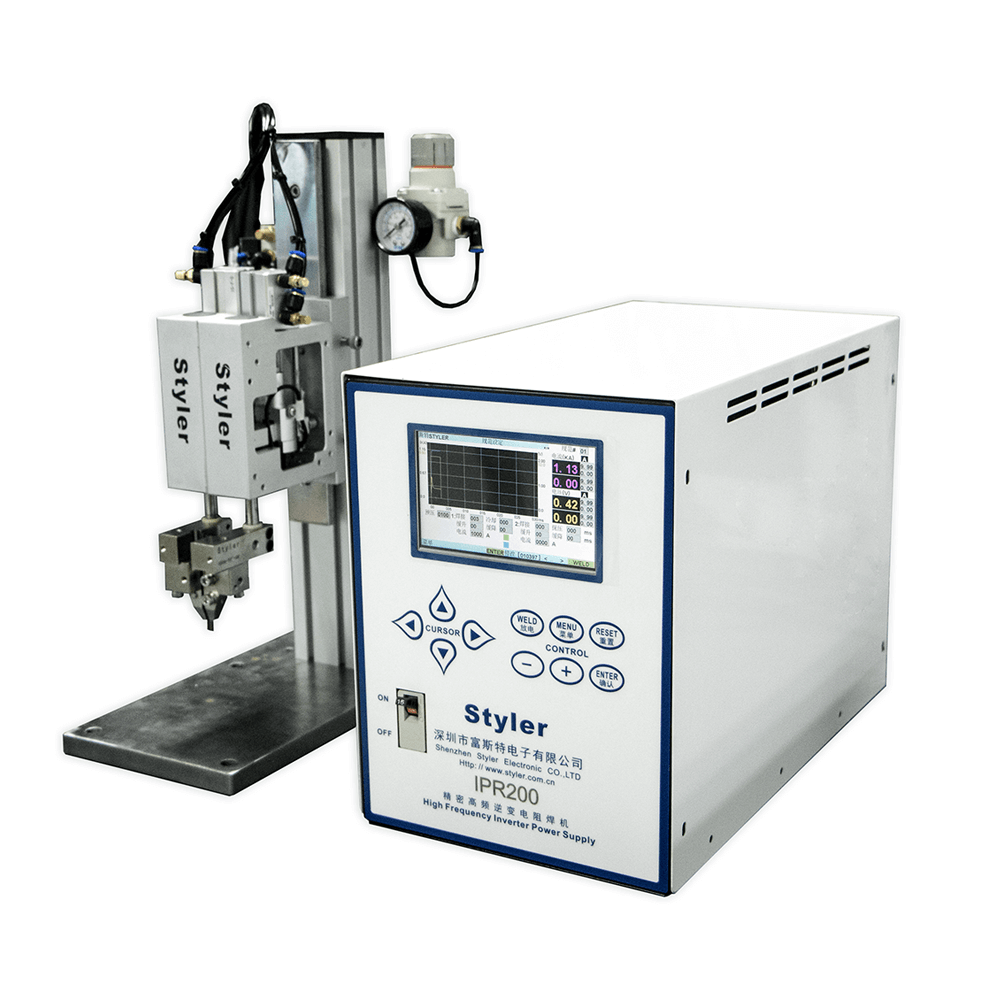

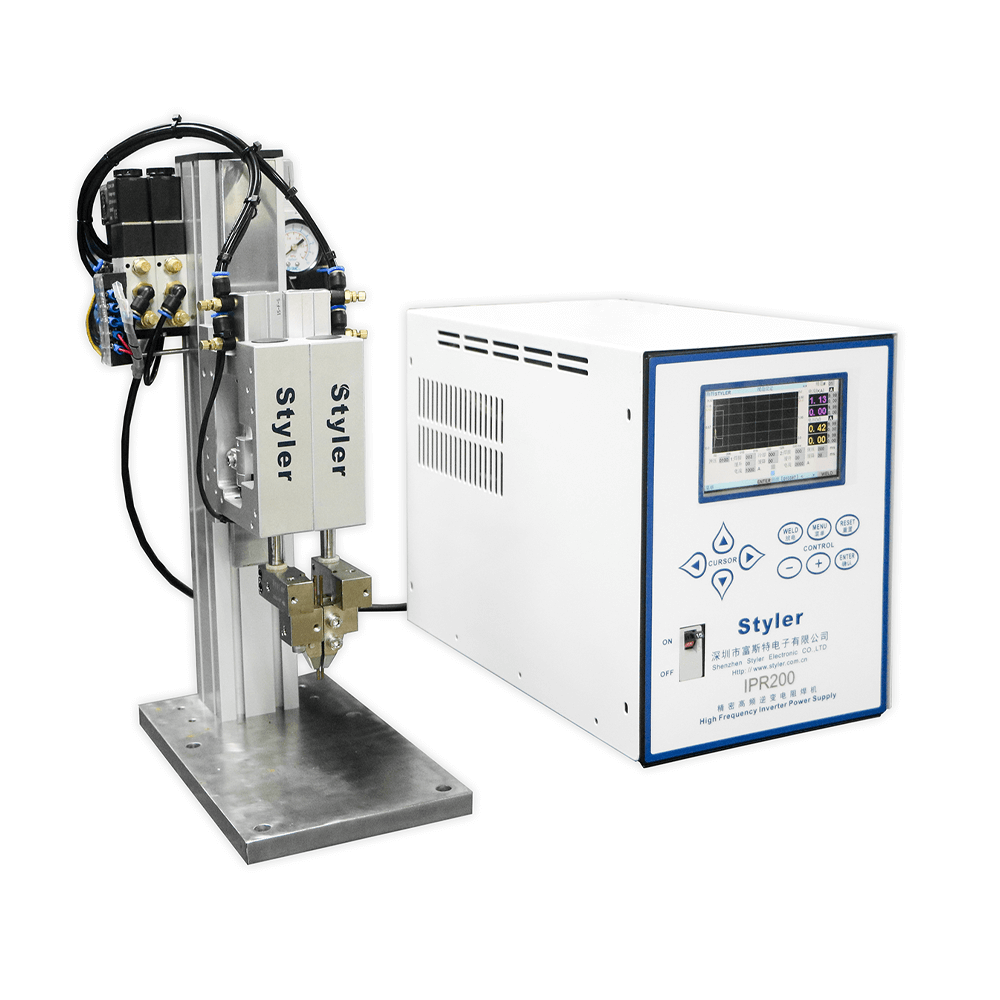

IPV200 Resistance Welding Machine

Iimpawu zeMveliso

Ulawulo lwangoku olusisiseko, ulawulo lwamandla ombane rhoqo, ulawulo oluxubeneyo, ukuqinisekisa ukwahlukana kwe-welding. Izinga lolawulo oluphezulu: 4KHz.

Ukuya kuthi ga kwimemori ye-welding ye-50 egciniweyo, ukuphatha i-workpiece eyahlukileyo.

Ukutshiza okuncinci kwe-welding kwisiphumo esicocekileyo nesilungileyo se-welding.

Ukuthembeka okuphezulu kunye nokusebenza okuphezulu.

Iinkcukacha zeMveliso

Uphawu loyelelwano lweParameter

| MO DEL | IPV100 | IPV200 | IPV300 | IPV500 |

| ELEC TRICAL PARAMETERS | ubuninzi becurr:1500A | ubuninzi becurr:2500A | ubuninzi becurr:3500A | ubuninzi becurr:5000A |

| ELEC TRICAL PARAMETERS | akukho volt yomthwalo: 7 .2V | akukho-mthwalo volt: 8.5V | akukho mthwalo volt 9 | akukho-mthwalo volt: 10V |

| igalelo: 3 isigaba 340 ~ 420VAC 50/60Hz | ||||

| UXABISO LOMANDLA WOKUGUQULA | 3.5KVA | 5.5KVA | 8.5KVA | 15KVA |

| ULAWULO | ngokuyintloko const curr, const . i-volt , i-volt ye-contro edibeneyo: 00.0% ~ 99 .9% | |||

| UKULAWULWA UKUCHANEKA | icurr:200~1500A | icurr:400~2500A | icurr:400~3500A | icurr:800~5000A |

| ukunyuka okucothayo 1, ukunyuka okucothayo 2:00 ~ 49ms | ||||

| ixesha lokuwelda 1:00 ~ 99ms; ixesha welding 2:000 ~ 299ms | ||||

| ixesha lokunciphisa ixesha 1; ucotha ixesha 2:00 ~ 49ms | ||||

| Ichongiwe ixabiso lecurr eliyincopho: 0-8000 | ||||

| UKUBEKA IXESHA | ixesha loqhagamshelwano loxinzelelo: 0000 ~ 9999ms | |||

| ixesha lokupholisa ipali yokuwelda: 000 ~ 999ms | ||||

| ixesha lokubamba emva kwe-welding: 000 ~ 999ms | ||||

| INDLELA YOKUPHOLISA | umoya | |||

| EX.SIZE | 215(W)X431( D)X274(H)mm | |||

| UBUKHULU BOKUPAKA | 280(W)X530( D)X340(H)mm | |||

| GW | 17KG | 23KG | ||

Izincedisi ozikhethelayo

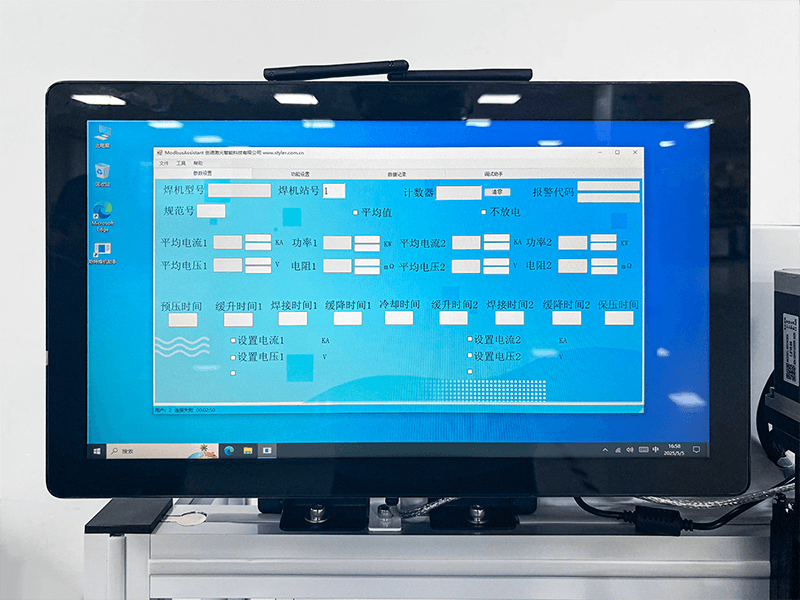

Ikhompyuter (ixesha langempela lokujongwa kwee-solder joints, idatha ingathunyelwa nge-RS485)

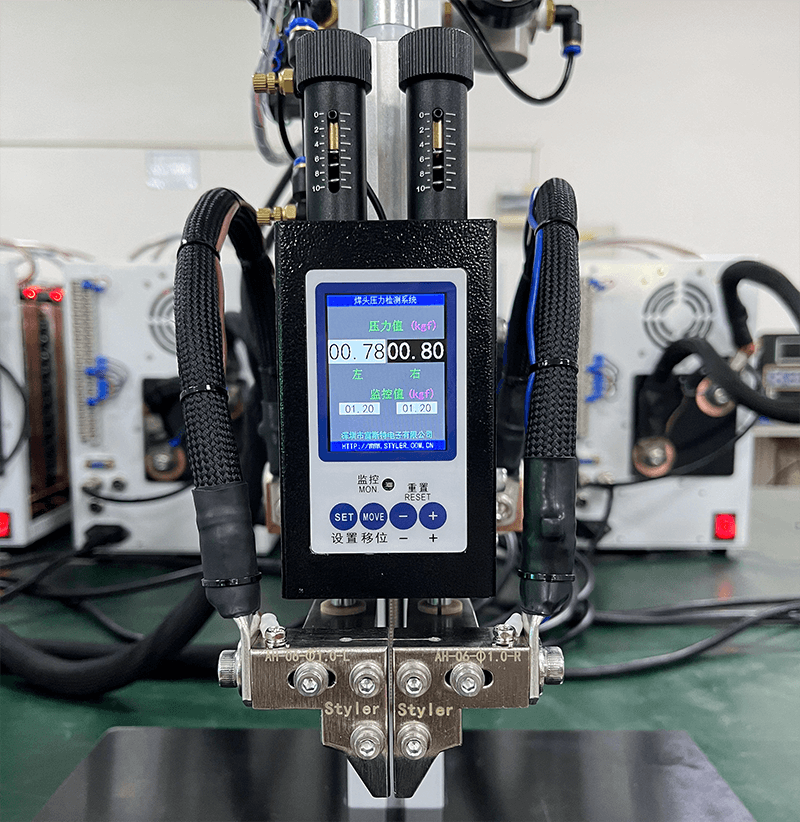

Yongeza inzwa yoxinzelelo kwintloko ye-welding (uxinzelelo lwee-clamps kumacala omabini lunokusetwa ukuba luhambelane, kwaye uxinzelelo ngexesha le-welding lunokubekwa iliso)

Kutheni Khetha Thina

-Ngaba sixhasa OEM okanye ODM?

-Ingaba ipeyinti yokuqala ye-R&D yokwenziwa kwepeyinti iya kuba nenzuzo yexabiso?

-Ingaba iimveliso ezikumgangatho ophezulu?

-Ngaba sineqela elilungileyo?

-Ngaba imveliso yethu iyayixhasa inkonzo yasemva kokuthengiswa kwehlabathi?

-Ngaba imveliso yethu iqinisekisiwe?

yonke impendulo ithi "EWE"

Ulwazi lweNzululwazi oludumileyo

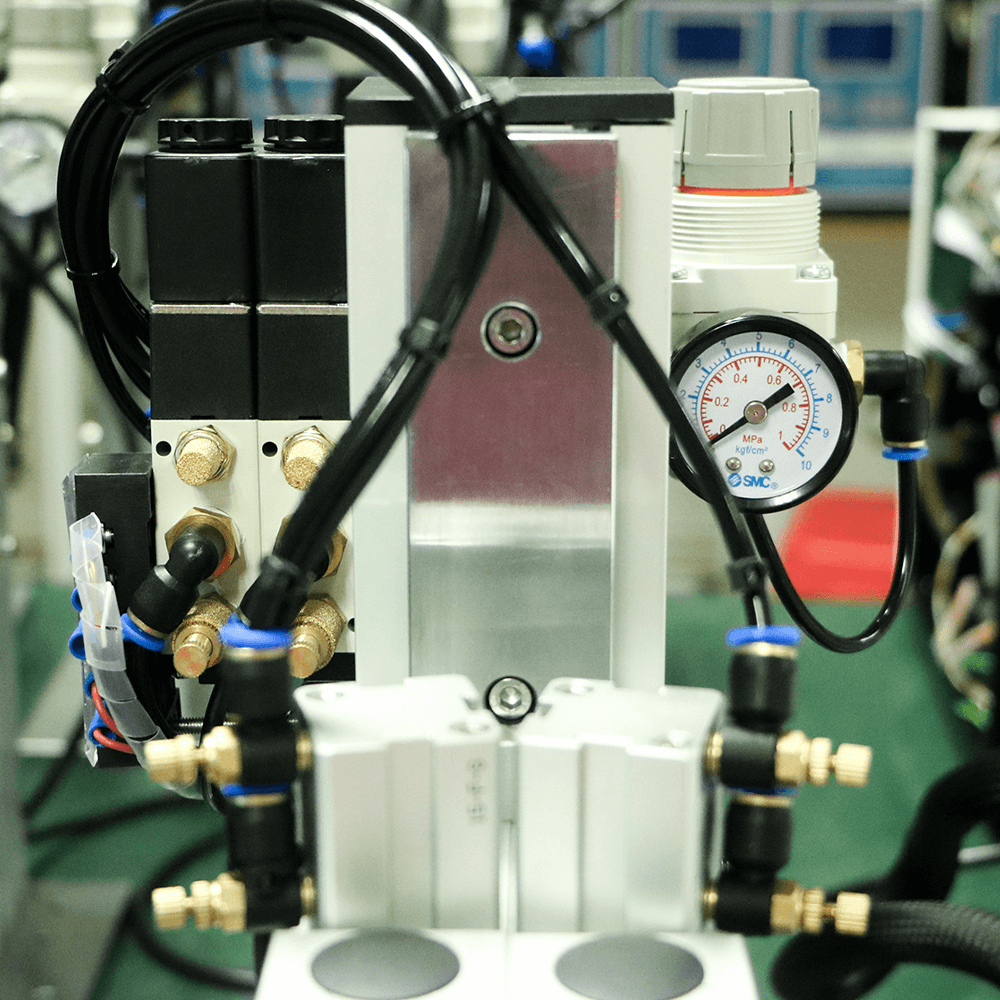

Lo matshini wokuwelda indawo we-pneumatic usetyenziswa ikakhulu kwi-18650 cylinder call pack welding, inokuwelda ubukhulu bethebhu ye-Nickel ukusuka kwi-0.02-0.2 mm kunye nesiphumo esihle sokuwelda.

Imodeli ye-Pneumatic inomthamo omncinci kunye nobunzima, kulula ukuthunyelwa kwamanye amazwe.

Inaliti ye-Sinlge ingasetyenziselwa i-Ni tab weld kunye ne-Stainless steel case.

1. Ulawulo lweMicrocomputer, uhlengahlengiso lwangoku lweCNC.

2. Amandla e-welding aphezulu.

3. Isiboniso ityhubhu yedijithali, ulawulo lwebhodi yezitshixo, iparameters welding flash storage.

4. I-welding ye-pulse kabini, yenza i-welding iqine ngakumbi.

5. Iintlantsi ezincinci ze-welding, i-solder joint uniform imbonakalo, umphezulu ucocekile.

6. Amaxesha e-welding angamiselwa.

7. Unokuseta ixesha lokulayisha kwangaphambili, ixesha lokubamba, ixesha lokuphumla, isantya se-welding sinokulungiswa.

8. Amandla amakhulu, azinzileyo kwaye anokwethenjelwa.

9. Uxinzelelo lwenaliti ephindwe kabini ehlengahlengiswayo ngokwahlukileyo, Ilungele ukutyeba okwahlukileyo kwe-Nickel strip.