Iimveliso

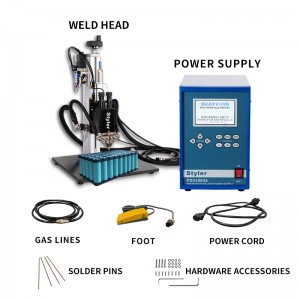

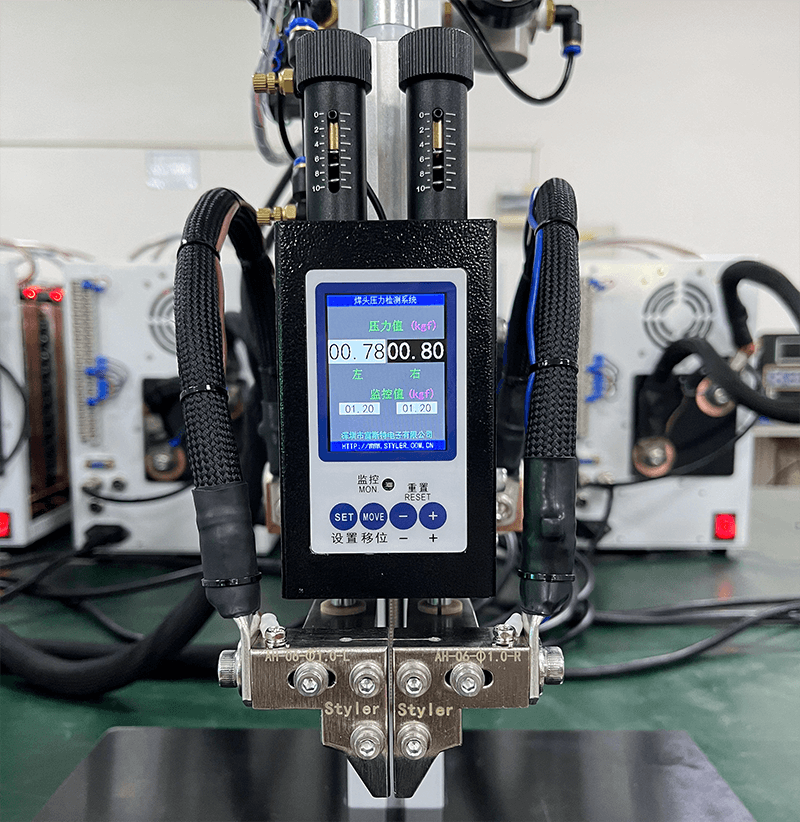

PDC6000A Umatshini wokuwelda indawo

Iimpawu zeMveliso

Eyona ndlela iphambili yangoku, i-voltage engaguqukiyo kunye nemowudi yolawulo ye-hybrid yamkelwe ukuqinisekisa ukuhlukahluka kwenkqubo ye-welding.

Isikrini esikhulu se-LCD, esinokubonisa i-welding yangoku, amandla kunye ne-voltage phakathi kwe-electrode, kunye nokumelana noqhagamshelwano.

Umsebenzi wokukhangela owakhelwe ngaphakathi: phambi kombane osemthethweni, ukukhangela okwangoku kungasetyenziselwa ukuqinisekisa ubukho bomsebenzi kunye nobume bomsebenzi.

Umthombo wamandla kunye neentloko ezimbini ze-welding zinokusebenza ngexesha elinye.

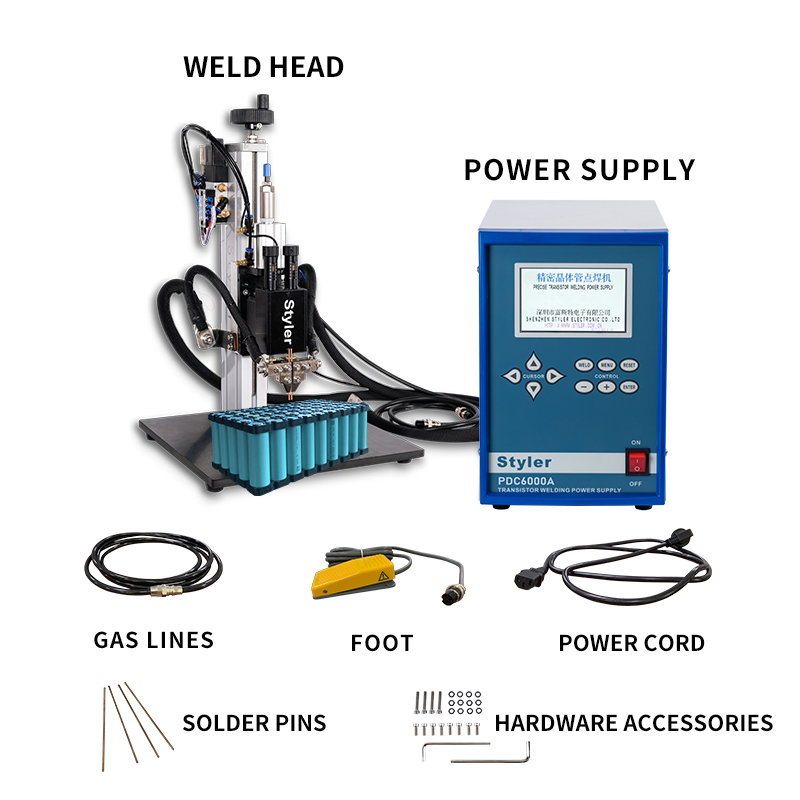

Iiparamitha ze-welding zangempela zinokukhutshwa nge-RS-485 ye-serial port.

Ungatshintsha amaqela angama-32 amandla ngokungenasizathu ngamazibuko angaphandle.

Imiqondiso epheleleyo yegalelo kunye nemveliso, enokusetyenziswa ngokubambisana neqondo eliphezulu lokuzenzekelayo. Unokuguqula ukude kwaye ufowunele iiparamitha ngeModbus RTU protocol.

Isicelo seMveliso

Iyakwazi ukuwelda izinto ezahlukeneyo ezikhethekileyo, ngakumbi zilungele ukudityaniswa okuchanekileyo kwentsimbi, ubhedu, i-aluminium, i-nickel, i-titanium, i-magnesium, i-molybdenum, i-tantalum, i-niobium, isilivere, iplatinam, i-zirconium, i-uranium, i-beryllium, ilothe kunye ne-alloys yazo. Izicelo ziquka iitheminali ze-micromotor kunye neengcingo ezinamelled, iplagi-in components, iibhetri, optoelectronics, cables, piezoelectric crystals, amacandelo anovakalelo kunye ne-sensor, ii-capacitors kunye nezinye izinto zombane, izixhobo zonyango, zonke iintlobo zamacandelo e-elektroniki aneekhoyili ezincinci ezifuna ukudityaniswa ngokuthe ngqo kunye ne-enamelled iingcingo ezingenakuhlangabezana neemfuno ze-welding kunye nezinye izixhobo ze-welding kunye nezinye izixhobo ze-welding. iimfuno zenkqubo.

Iinkcukacha zeMveliso

Uphawu loyelelwano lweParameter

| Iiparamitha zesixhobo | |||||

| UMZEKELO | PDC10000A | PDC6000A | PDC4000A | ||

| MAX CURR | 10000A | 6000A | 2000A | ||

| MAX AMANDLA | 800W | 500W | 300W | ||

| UHLOBO | STD | STD | STD | ||

| MAX VOLT | 30V | ||||

| Igalelo | isigaba esinye 100 ~ 120VAC okanye isigaba esisodwa200 ~ 240VAC 50/60Hz | ||||

| ULAWULO | 1 .const , icurr i-curr kunye ne-volt indibaniselwano;4 .const amandla;5 .const .curr kunye nokudibanisa amandla | ||||

| IXESHA | ixesha loqhagamshelwano loxinzelelo: 0000 ~ 2999ms ukuchasana kwangaphambili ukubonwa ixesha welding: 0 .00 ~ 1 .00ms ixesha lokubhaqwa kwangaphambili: 2ms(zilungisiwe) ixesha lokunyuka: 0 .00 ~ 20 .0ms ukumelana nokubonwa kwangaphambili kwe-1, i-2 ixesha le-welding: 0 .00 ~ 99 .9ms ixesha lokucotha: 0 .00 ~ 20 .0ms ixesha lokupholisa: 0 .00 ~ 9 .99ms ixesha lokubamba: 000 ~ 999ms | ||||

| IISETHINGI

| 0.00~9.99KA | 0.00 ~ 6.00KA | 0.00 ~ 4.00KA | ||

| 0.00~9.99v | |||||

| 0.00~99.9KW | |||||

| 0.00~9.99KA | |||||

| 0.00~9.99V | |||||

| 0.00~99.9KW | |||||

| 00.0~9.99MΩ | |||||

| I-CURR RG | 205(W)×310(H)×446(D) | 205(W)×310(H)×446(D) | |||

| IVOLT RG | 24KG | 18KG | 16KG | ||

Izincedisi ozikhethelayo

Ikhompyuter (ixesha langempela lokujongwa kwee-solder joints, idatha ingathunyelwa nge-RS485)

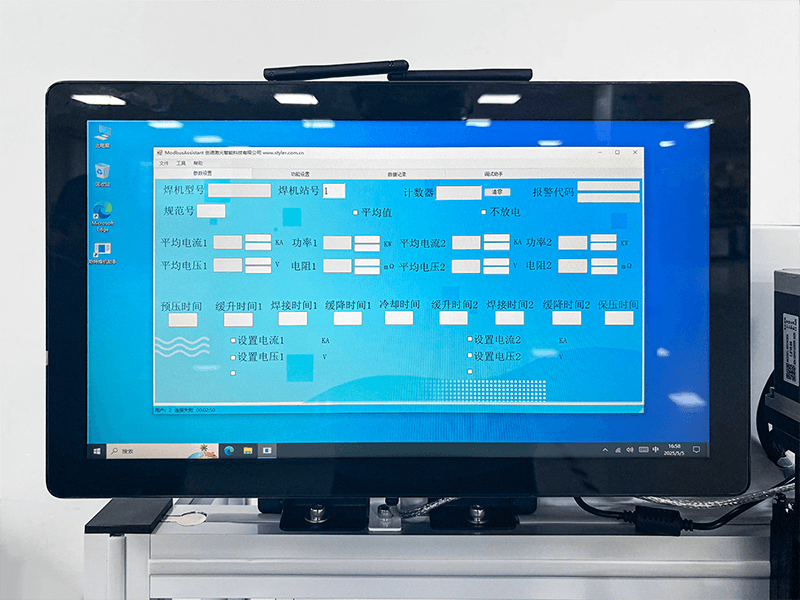

Yongeza inzwa yoxinzelelo kwintloko ye-welding (uxinzelelo lwee-clamps kumacala omabini lunokusetwa ukuba luhambelane, kwaye uxinzelelo ngexesha le-welding lunokubekwa iliso)

Kutheni ukhethe thina

1. Siye sigxininise kwintsimi ye-welding echanekileyo yokuchasana iminyaka eyi-12, kwaye sineemeko zoshishino ezityebileyo.

2. Sinobuchwephesha obungundoqo kunye nobuchule obunamandla be-R & D, kwaye sinokuphuhlisa imisebenzi eyenzelwe umntu ngokweemfuno zabathengi

3. Sinokukunika uyilo lwenkqubo ye-welding yobungcali.

4. Iimveliso kunye neenkonzo zethu zinegama elihle.

5. Sinokubonelela ngeemveliso ezingabizi kakhulu ngokuthe ngqo kumzi-mveliso.

6. Sinoluhlu olupheleleyo lweemodeli zemveliso.

7. Singakunika ingcali yokuthengisa kwangaphambili kunye nokubonisana emva kokuthengisa kwiiyure ezingama-24.